a table and shou shugi ban

Saturday, February 8, 2020 at 1:28PM

Saturday, February 8, 2020 at 1:28PM

The shop display room needed another table. I went to my favorite diy furninture designer Ana White's site and looked at plans. So the first table was a bust. Even if I had gotten it completely square, it was not sturdy enough for the life it would have led with the boyos. Think knives, cutting boards, and many knife crazy people. It was not going to work. So, it is now in the leather shop being a surface that we do not have to worry about knocking over.

I looked further and decided to use her farmhouse console table as a go by. I used the dimensions we were needing. I added another shelf. Instead of running to the hardware store, I used wood from other projects. Not bad if I say so myself. It is not perfect. I learn something new every time.

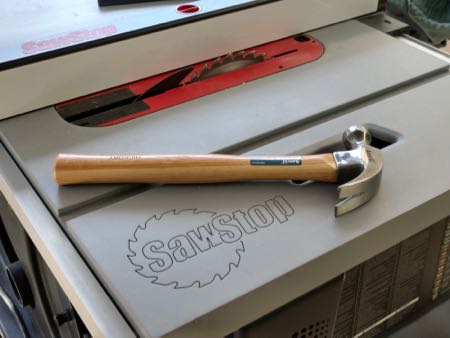

One of the new things I learned was the shou shugi ban technique. It is a Japanese wood burning technique that is used to preserve siding. But of course, people have taken it other places. One of those is ax handles.

How does that piece of information relate to this table top? The top was used as an experiment and an example of shou shugi ban for people who may want it used on there ax handles. That very in thing right now about throwing them while drinking. Some of these people like how it changes the grip on the handle.

I sanded the top whole down to where I wanted it. Then I burned the top. Sanded it a bit more so the charcoal would not mark anything else and oiled it. I am very pleased with how the top came out.

I stained the bottom with a vintage white stain. I was planning on coming back from my travels and applying polyurethane. It is in use already. I might get a chance. I might not.

Would I build another of these tables? Yes. It would be better too but I know I would make different mistakes.

furniture,

furniture,  wood working

wood working